Automotive design | Hitachi | 2025

Creating a New Phygital Excavator Concept

Hitachi Europe, in collaboration with Granstudio, has reimagined the future of Hitachi excavators with an innovative concept unveiled at Bauma 2025. This visionary design aims to shape the next generation of excavators through the seamless integration of advanced technology, enhancing user experience and transforming the machine into a natural extension of the operator’s hand.

The future of construction machinery isn’t just about performance—it’s about making machines that feel natural, that integrate with their users seamlessly, and that make work easier, not harder.

— Francesco Quaranta, President & CEO at Hitachi Construction Machinery (Europe) NV.

Shaping the Future of Excavators

Hitachi, a leader in construction equipment, wanted to create something that truly reflects their user-focused vision. For Bauma 2025, they introduced Landcros One—an excavator concept designed to feel like a natural extension of the operator, thanks to smart, seamless technology integration.

Granstudio worked closely with Hitachi to bring this concept to life. By focusing on the operator’s needs, we designed a machine that’s intuitive, easy to use, and future-ready.

Exterior Research

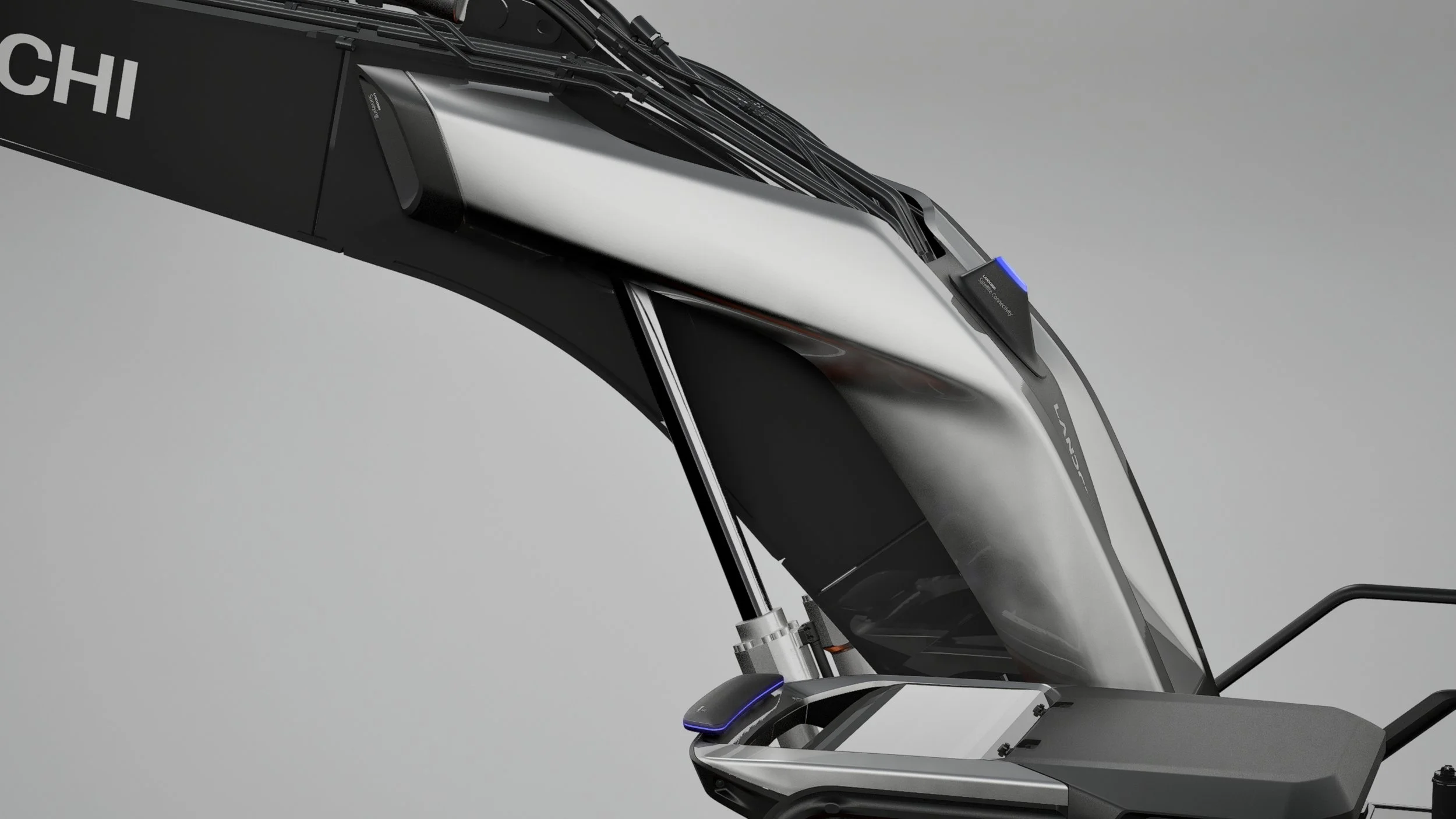

Hitachi has a strong and recognizable brand identity. During the exterior research phase, we focused on reinforcing these core elements while integrating technology and protective features directly into the design.

The result is a concept that improves safety and expresses Hitachi’s forward-looking vision, while staying true to the brand’s heritage and making the machine instantly recognizable as Hitachi.

Seamless Technology Integration

Advanced technology only matters when it truly supports the operator—making their job easier, not more complex.

Hitachi envisioned a future where technology becomes a natural extension of the operator. At Granstudio, we brought that vision to life through a design that feels intuitive and effortless in daily use.

With AI, the machine can assist with repetitive tasks, lower the learning curve, and boost efficiency. We translated this into a user-friendly, intelligent interface that keeps the operator fully in control.

LiDAR technology was also integrated to improve visibility and reduce risk, enhancing both safety and machine durability—further reflecting Hitachi’s commitment to smart, human-centered design.

Remote Operation for a Connected Future

Hitachi also envisioned new control modes, including fully remote operation, unlocking the potential for global jobsite management. What if an operator could control a machine from across the world?

We translated this ambition into a design that accommodates remote operation fluidly, making it a natural part of the excavator’s functionality.

“In this new era of tech, Granstudio's user-driven approach pinpoints which strategies and solutions create real value. ”

— LOWIE VERMEERSCH, FOUNDER & CREATIVE DIRECTOR.

“Good design is about making technology disappear into usability”

— LUIS DE SANTOS, AUTOMOTIVE DESIGNER

Phygital Cabin

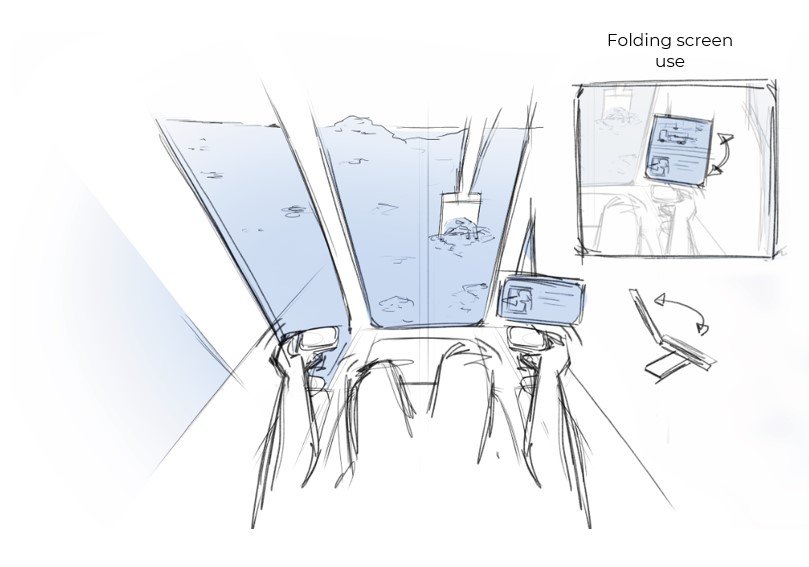

The cabin design was a central focus of this project. Operators spend countless hours inside their machines, yet many current excavators have cluttered screens that reduce visibility, poorly positioned buttons, and controls that go unused or are difficult to reach.

Our goal was to streamline the design, removing anything unnecessary and ensuring that every interaction feels natural and effortless. We focused on seamless technology integration, embedding only what enhances usability, rather than adding complexity.

Every touchpoint—physical or digital—was carefully designed to create a true phygital experience, where digital intelligence and physical control merge intuitively into the operator’s workflow.

Nowadays, operating environments are complex, with multiple screens that create distractions and make work more difficult.

We reimagined the user experience by reducing cabin elements, enhancing visibility, and simplifying daily operations.

Bauma 2025

For Bauma 2025, we went beyond the design phase. Together with Hitachi’s team, we built a full-scale physical concept model of the excavator to bring the project’s vision to life. Starting from initial sketches and renders, we followed the entire development process through to production.

Building a concept means testing ideas in the real world—turning them into something tangible that people can relate to. Especially in a context like Bauma, where innovation must be seen, experienced, and understood, the physical model became a key part of telling the story behind the design.